Infrastructure from Prof. Van Geem

BSSC | Bench scale reactor The setup is equipped with 2 furnaces, including 2 reactors: - Tubular metal reactor - Quartz or a silicon-coated metal reactor The setup is usually operated isothermally, which is ideal for kinetic studies of pyrolysis and steam cracking. Fouling formation can be measured for both reactors. Residence times relevant to the steam cracking process (0.2-0.5 s, up to 1s) can be achieved. The feed section allows feeding and co-feeding of gases and liquids up to heavy feeds such as full-range crude oil. The analysis section uses comprehensive two-dimensional gas chromatography in combination with 3 detection techniques (FID, MS, and SCD), allowing analysis of the entire reactor effluent using high-temperature columns. The quantification is based on internal standard methods. |

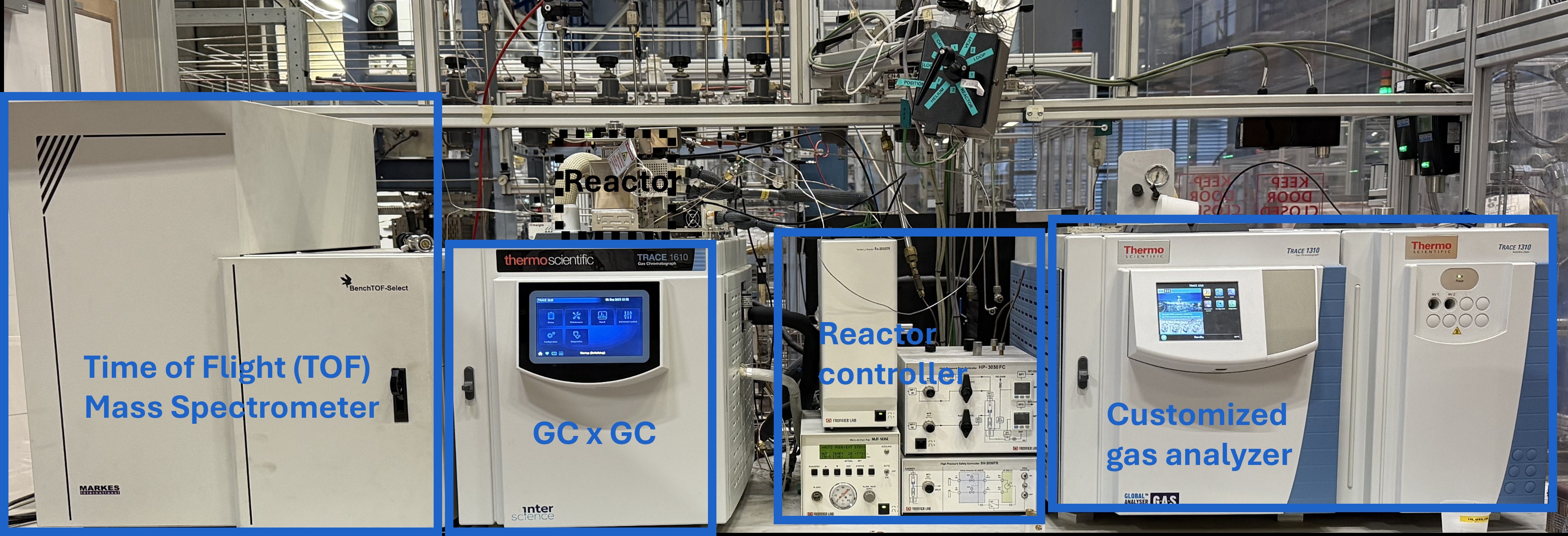

µ-pyrolizer | Micro-pyrolizer The setup is employed for fast pyrolysis, catalytic pyrolysis or thermal decomposition of small samples (typically <0.5mg, solid or liquid). It consists of single-shot tandem micro-reactors (Rx-3050tr, Frontier Labs, Japan, No. 1 in picture), coupled with two-dimensional gas chromatography (GC×GC, No. 2) and a separate customized multicolumn GC (Trace 1300, No. 4) for analysis of light gases. The reactors are capable of rapid heating/cooling, and the temperature zones are independently controlled. The online analysis section is equipped for product identification with a BenchTOF-Select™ (Markes, UK, No. 3). The unit works at allowable GC inlet pressures (160-280 kPa) and the temperature can be set between -40 and 700°C (stainless steel tube), or up to 900°C (quartz tube). |

JSR-PFR | Jet stirred reactor - plug flow reactor The plug flow reactor (PFR) setup is aimed at performing steam cracking experiments (feed ranges from ethane to light naphtha) for conversion into light olefins. Gaseous hydrocarbons are fed directly to reactor, operated around 750°C and 1-2 bar pressure. The central part of the reactor holds a coupon, which is fitted to a kanthal wire and centered in the crystal reactor, with the heating elements mounted in a circle configuration to achieve the desired reactor temperature in a uniform way. Products from this setup are analyzed using two gas chromatography (GC) devices. Hydrocarbons with carbon number less than 4, are identified and quantified by refinery gas analyzer, whereas hydrocarbons with higher carbon number are identified and quantified via GC with FID (flame ionization detector |

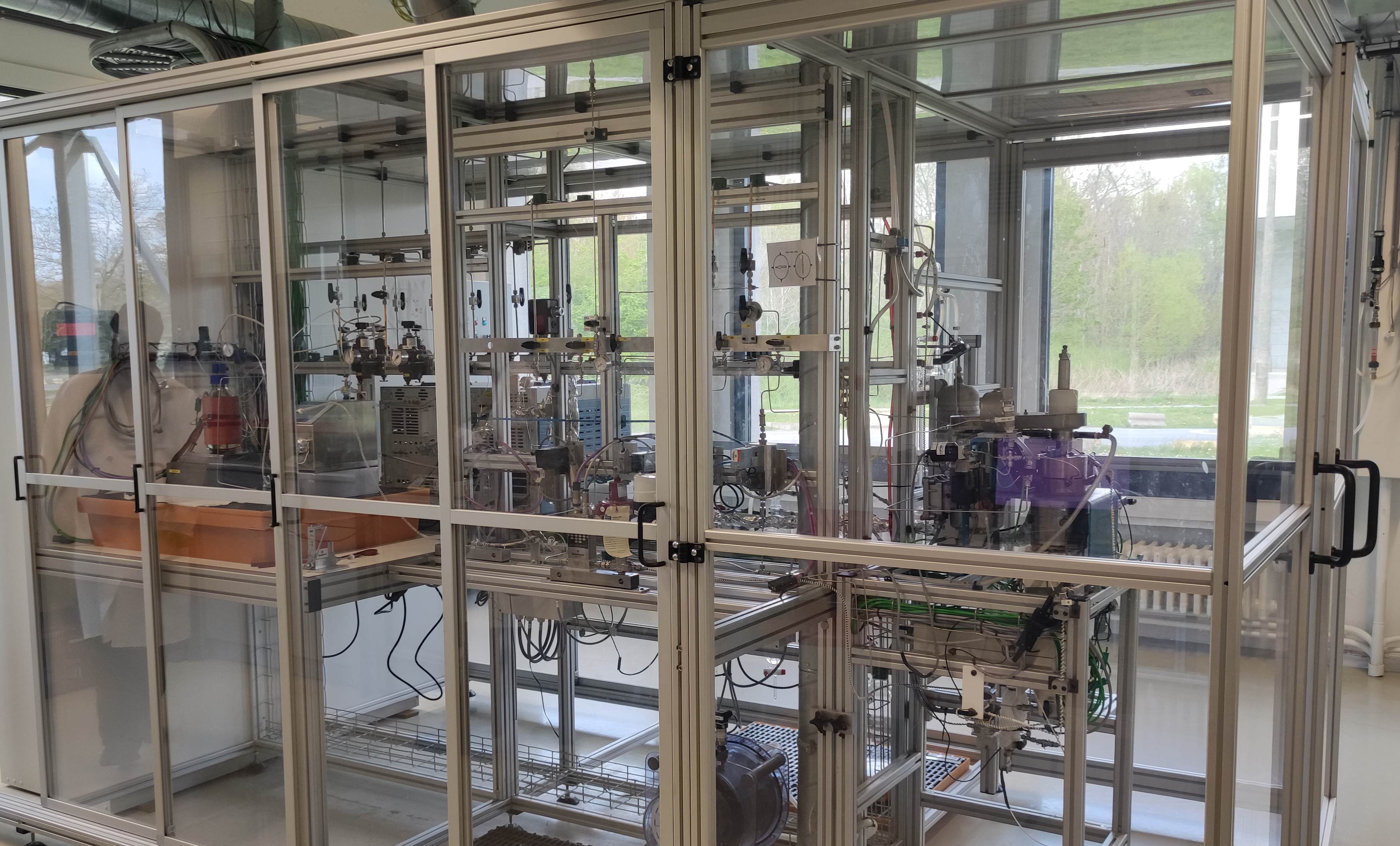

| Steam cracker | Pilot Steam Cracker This experimental setup is used to determine the yields of cracking reactions and/or coke deposition in the radiant/convection sections of coils and the transfer line exchanger (TLE). The major advantage of the pilot is its extreme flexibility. A wide variety of hydrocarbons, ranging from gaseous feeds to hydrocarbon liquids and to waxes, can be handled. The reactor design facilitates a wide array of process conditions, with normal hydrocarbon flow rates ranging from 3 to 4 kg/h and the capability to reach high temperatures up to 900 °C in the furnace. The pilot also offers the opportunity to test steam cracking of industrially new feeds, additives, optimization of process conditions, coatings, etc. The setup comprises three sections: the feed section with feeding barrels and Coriolis flow meters, the reactor and furnace section, and the analysis section featuring online product analysis through gas chromatography with various detectors such as FID, SCD, NCD, and AED. Additionally, the system is equipped with a Refinery Gas Analyzer (RGA) and an infrared meter to measure light hydrocarbons, carbon monoxide and carbon dioxide in the product. |

FAST | Fouling Assessment Setup The FAST setup is capable of conducting steam cracking reactions and coke measurements through both offline and online methods. In the online approach, a coupon is suspended in the reactor and coke formed during reaction is monitored over time to measure catalytic and asymptotic coking rates. During offline coke measurement analysis, the coke formed on the inner wall of the reactor tube during steam cracking reactions is burnt and the combustion gases are measured using Infrared spectroscopy (IR), correlating the results to the mass of the formed coke. Additionally, during experiments, the effluent products of steam cracking are analysed online using a Refinery Gas Analyzer (RGA) and GC×GC. The feedstocks utilized in FAST are liquids, with the operating pressure and temperature set at 1.8 bar and 900-1050°C, respectively. |

Infrastructure from Prof. Thybaut

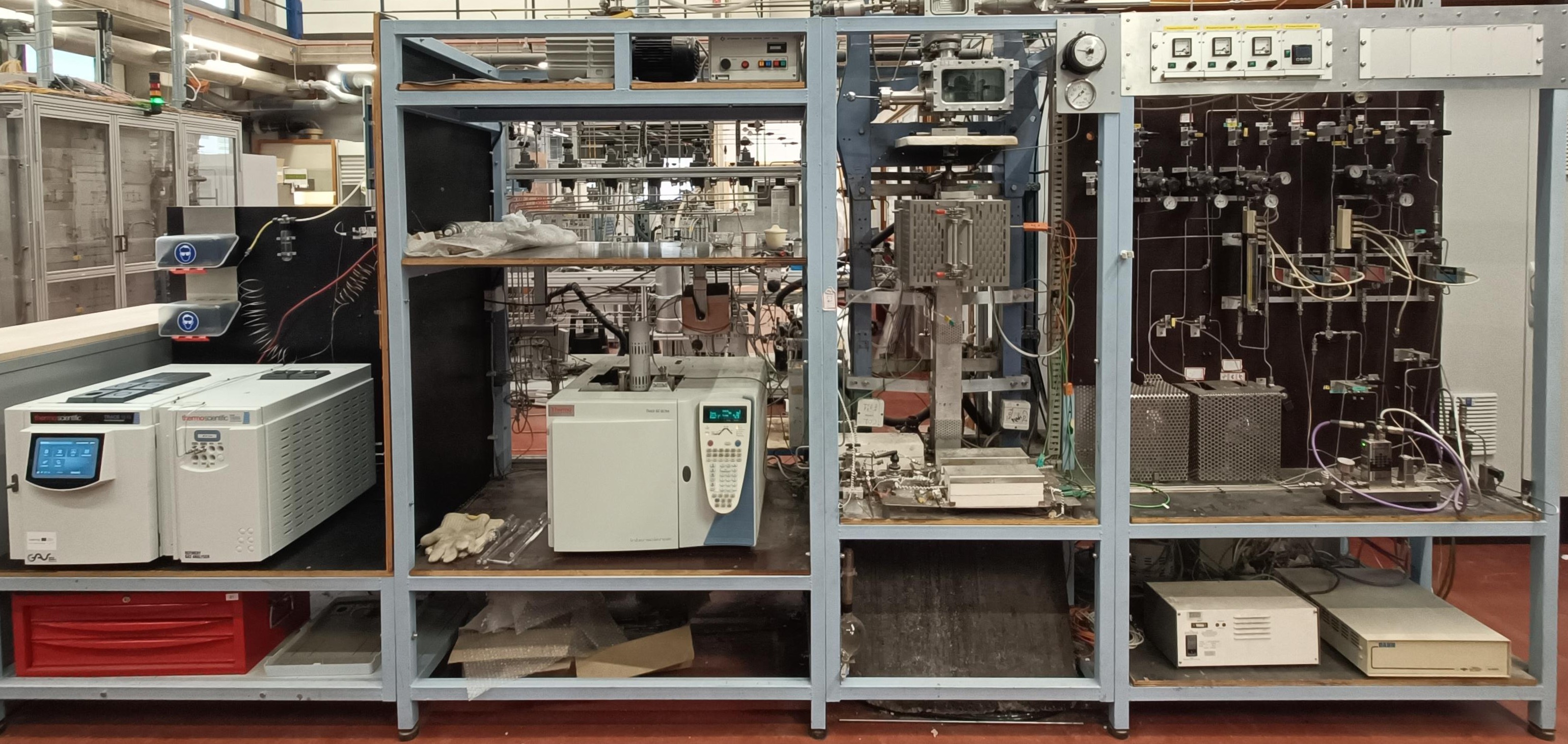

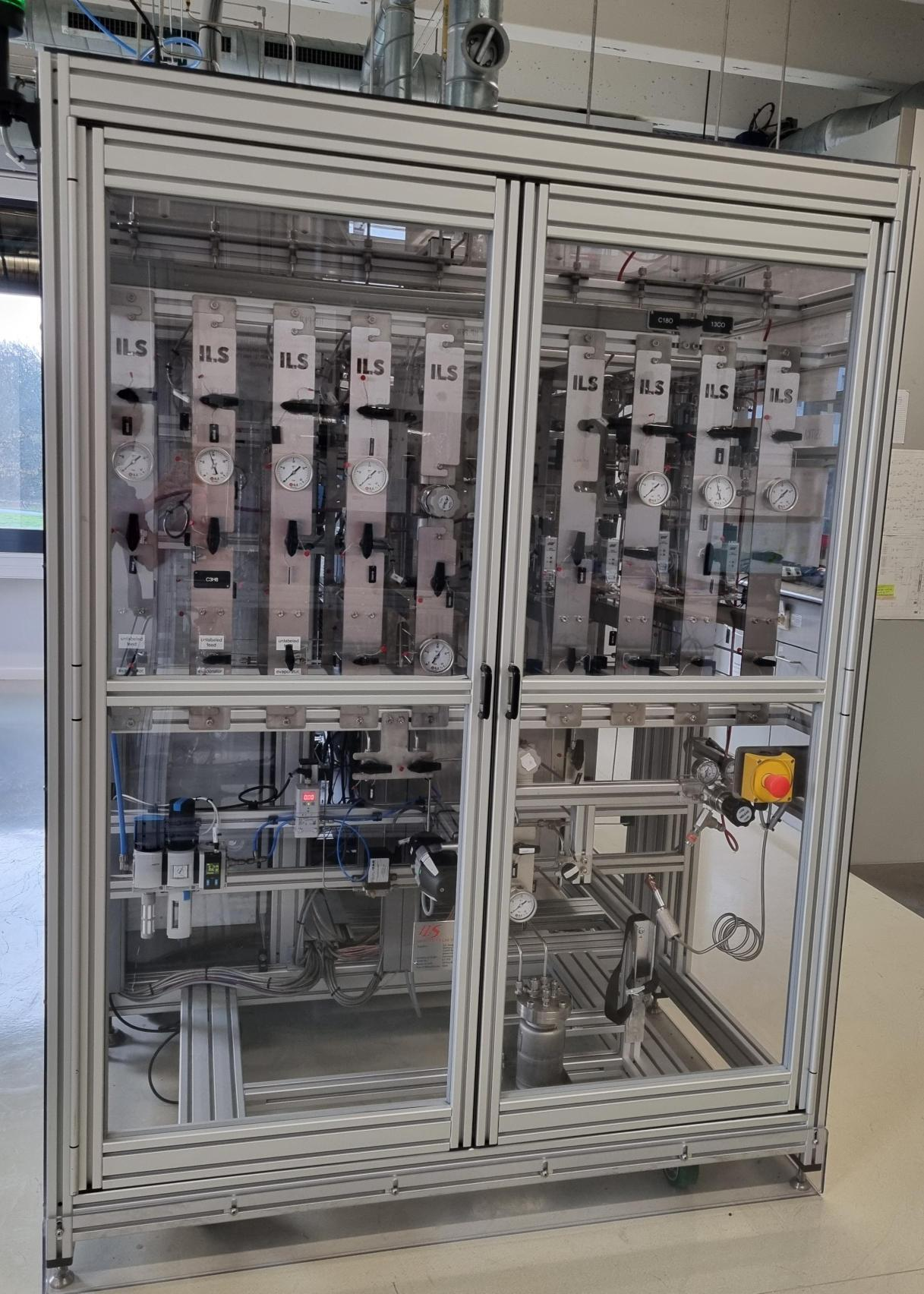

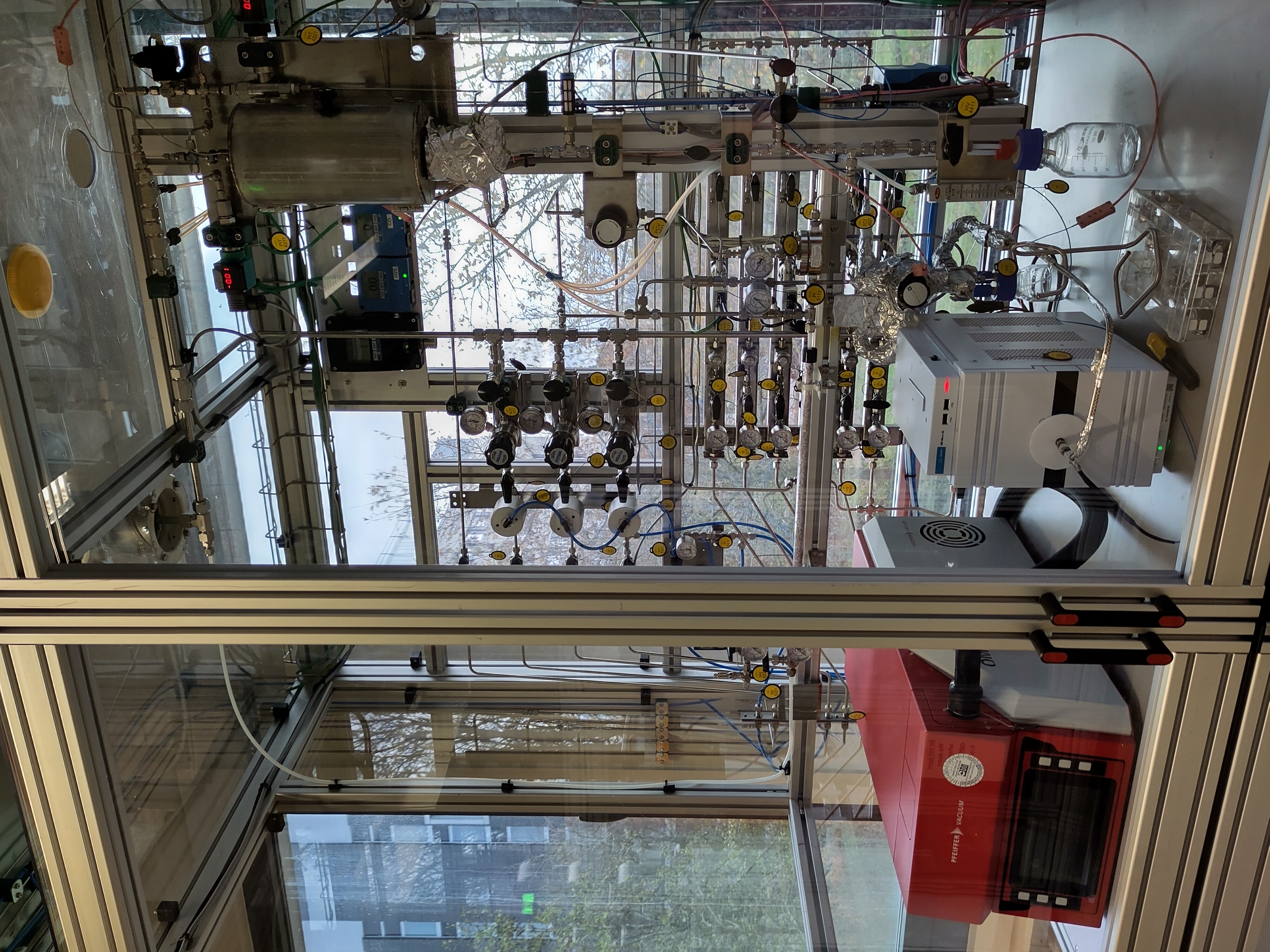

HTK-I | High-throughput Kinetics I System of 8 parallel plug-flow reactors for fast kinetic data acquisition. The 8 reactors are embedded in 4 furnaces, with individual control of pressure and temperature in each block. Possibility to feed 3 gas components per reactor from 3 different MFC: CH4 , N2 and optional H2 . One liquid pump is installed as an optional liquid flow per reactor. Pressures ranging from 0 to 100 bar, temperatures up to 500°C, amount of catalyst required in the scale of grams. Two GC chromatographs available with FID detector for online analysis of the gasses and offline analysis of liquid by an autosampler. |

HTK-II | High-throughput Kinetics II Fast parallel reactor system for catalyst screening, comprising 16 reactors in 4 separate blocks. Possibility to feed 3 gas components per reactor from 3 different MFCs: syngas, N2 and H2. Also liquid feed available through HPLC (flow range of 0.8-40g/h). Pressures ranging from 0 to 80 bar, temperatures up to 500°C, milligram scale of catalyst required. GC chromatograph available with FID and TCD detectors for online analysis of the gasses. |

Berty | Gas-phase continuous stirred tank reactor with solid catalyst The Berty reactor set-up embodies a Continuous Stirred Tank Reactor, which is built up from a 1.45L hollow cylinder, comprising a basket to load a solid catalyst. The maximum work temperature is 530°C at which pressures up to 50 bar are still allowed. It is possible to feed 2 gases to the reactor from two different MFCs, typically N2 and H2. An HPLC pump is installed to provide a liquid feed flow rate to the reactor (0.002 – 2.5 mL.min-1). Internal standard is added after the reactor (CH4). One GC-FID is available for online analysis of the gasses. |

Robinson-Mahony | Multiphase continuous stirred tank reactor with solid catalyst The Robinson-Mahony (RM) is a bench scale experimental setup used for acquiring kinetic data up to a pressure of 120 bar and temperatures up to 350°C. It consists of a three-phase gradient-free continuously stirred tank reactor (CSTR), equipped with an annular catalyst basket, and is typically used for studying hydrotreating and hydrocracking reactions with fossil or circular feedstocks, such as pyrolysis oil from plastics and bio sources. The RM setup is built to handle feeds, which contain various kinds of sulphur, nitrogen and oxygen compounds. Analysis of the effluent stream is performed with a Trace 1310 Gas chromatograph (Thermo Scientific). It is equipped with three channels of detection i.e., two thermal conductivity detectors (TCD) and one flame ionization detector (FID). The TCD and FID channels can be used for the complete analysis of effluent gas and liquid samples. |

PARR | Parr batch reactor This batch reactor (Series 4560 Mini Reactors) is equipped with gas inlet valves, a liquid sampling valve and a pressure gauge in addition to the internal stirrer. It is commonly used for various reactions, including liquid-liquid, gas-liquid and solid-liquid. The size of the vessel is 350 mL and the maximum working temperature and pressure are 350 ℃ and 200 bar, respectively. |

Infrastructure from Prof. Saeys

SSITKA | Steady-State isotopic transient kinetic analysis SSITKA addresses the intrinsic kinetics of catalytic reactions by analysis of surface species and their residence times. The technique can decouple the effect of the concentration of intermediates and site reactivity on the catalytic activity. SSITKA is usually carried out close to atmospheric pressure, while also allowing for high-pressure experiments. A SSITKA experiment involves an abrupt switch from a regular to the corresponding isotopically labelled feed stream with identical flow and pressure. Steady state is maintained during the whole experiment, provided that no isotope effect occurs. The transient response of the product is recorded by a mass spectrometer and contains the kinetic information. The setup is custom-built and enables SSITKA experiments on solid materials in a plug flow fixed bed reactor for gas phase catalysis using: A liquid feed 5. Kr CO2 – switchable to isotope 6. Ar H2 – switchable to isotope 7. pressurized air A hydrocarbon or CO stream – switchable to isotope 8. Optional steam feeding Gas lines are heated, the catalyst bed (plug flow reactor) reaches > 900 °C. The reactor can be operated maximally at 25 bar overpressure. A high-pressure compatible MS detection system provides unique access to high pressure SSITKA experiments. |

CUPS | Catalytic Upgrading of Sulphur-containing gases The setup is a portable, laboratory-scale methanation reactor, designed to test the activity and stability of methanation catalysts. The internal lines of the setup (including up- and downstream of the reactor) consist of sulfinert/plastic lines. A feed section (upstream) consists of a series of mass flow controllers designed to flow CO2, CO, CH4, H2, O2, H2S, Ar, He, N2, or any (non-hazardous) combination of the proposed gases (e.g. BFG, post-combustion flue gas, biogas CO2/H2/CH4, diluted O2 in Ar, diluted H2S in Ar, …). Due to the portable nature of the setup, the pressure controllers are inside the setup (instead of in the gas cabinets) and can withstand gas pressures of 200 barg. A 4-way valve allows switching from reactive to inert Ar gas, controlled using a rotameter. A vacuum pump is installed if feed gas needs to be sampled on site. The reactor section comprises a fixed-bed reactor with oven with PID-based temperature control and a back-pressure regulator. Two types of reactors can be used: (i) a quartz tube (inner diameter: 7.3-7.5 mm) with overpressure release at 1 barg or (ii) a stainless-steel reactor with 12 barg overpressure release. Reactor and oven are designed to go up to temperatures of 600°C. A cooler removes condensable components in the product stream. The analysis section has multiple valve connections to take off-line gas samples in Tedlar bags for GC analysis (both for feed and product streams) and on-line MS and GC analysis (of product stream). |

HP-PFR | High-pressure plug flow reactor The unit may be used for catalyst testing e.g. for the conversion of synthesis gas (mixture of CO, H2 and optionally CO2) to methanol. It may also be used for CO2 hydrogenation, propane dehydrogenation with CO2, …. Depending on the process, the reactor system can be switched between high-temperature/low-pressure (17.5bar-850°C) and high-pressure/low-temperature (100bar-550°C). The setup uses only gas injection. The reaction effluents are analysed online using a TRACE-1310 GC analyser equipped with Rt-Ubond (FID), RTX-1 (FPD), Hayesep N and SC-ST (TCD 1), and RT-QBond and RT-MS 5A (TCD 2) columns. It can measure permanent gases (H2, He) by TCD, sulphur compounds by FPD and dimethyl ether, methanol and other elements by FID. |

OCM | Oxidative coupling of Methane A unique experimental setup developed in house is used to evaluate the performance of OCM catalysts under isothermal conditions. The unit can operate isothermally under various conditions with temperatures up to 950°C and total pressure up to 20 bar. The feed section has four independent gas feed lines (O2, CH4, N2, He) with flow rates regulated by thermal mass flow controllers (MFCs, Bronkhorst). Sintered α-Al2O3 is used as the reactor material because of its thermal properties at elevated temperatures and its inertness for OCM. The reactor is 90 cm long, with external diameter of 12 mm, and an internal diameter of 8 mm. A thermowell, also made from α-Al2O3 (external diameter of 4 mm), is placed in the centre of the reactor. A thermocouple can move along the entire length of the reactor to measure of axial temperature profile. The reactor is placed inside a fluidized sand bath, which serves as oven with near isothermal conditions, even for a fast and highly exothermic reaction such as OCM. A GC system custom-built by Bruker provides online analysis of the products with simultaneous determination of O2, N2, CO, CO2, CH4, C2, C3 isomers and CH2O in gaseous samples. |